Whether you’re a beginner or a professional contractor, using a table saw is an invaluable tool for creating precise cuts and accurate measurements. But did you know that you can make even more out of your table saw with the help of a zero clearance insert? Let’s explore what this insert does and how it can help improve your projects.

What Is A Zero Clearance Insert?

A zero clearance insert (or ZCI) is essentially an aftermarket accessory that fits into the throat plate of your table saw. It helps to reduce tear-out when cutting small pieces, which is often caused by the blade guard on most table saws. The ZCI also provides support to keep thin materials from drooping into the blade as you cut them. This makes it much easier to make accurate cuts without worrying about having them fall through the gap between the blade guard and throat plate.

How Does A Zero Clearance Insert Work?

A zero clearance insert works by providing an exact fit around the blade, which reduces the size of its opening and prevents thin pieces or pieces with narrow edges from slipping through. The ZCI also creates more stability for your workpiece so it won't vibrate or twist as you make your cut. Additionally, because there's less space between the blade and throat plate, there's less dust created during cutting operations, making it easier to keep things clean in your workspace.

Finally, when using a ZCI, you don't need to worry about adjusting the fence each time—it stays at one fixed setting since it's custom made for your specific saw model. This makes repeated cuts easier and faster since all you have to do is adjust the height of the blade instead of moving around the entire fence system every time.

Conclusion:

Using a zero clearance insert in your table saw can be an incredibly useful tool if you're looking for precise cuts and accurate measurements while working on projects in your shop or on job sites. Not only does it reduce tear-out but also eliminates dust buildup while providing extra stability for thin materials that might otherwise slip through between the blade guard and throat plate. Plus, since it's custom made for each model of table saw, once you install yours you won't have to worry about making any adjustments each time—you'll be ready to get straight back to work! With all these advantages combined, installing a zero clearance insert in your table saw is definitely worth considering if precision is important in your work!

Phenolic Zero Clearance Insert for Delta Uni-Saw Contractor | Large Grizzly and Other Table Saws with a 13-3/8” x 3-3/4” x 1/2” Throat Plate Opening

DELTA 3-PACK Zero Clearance inserts Fit 36-725, 36-725T2, 36-5152, 36-5000, 36-5000T2 Table Saws

FAQs

1. What is a zero clearance insert and why do you need one?

Answer: A zero clearance insert (or ZCI) is a vital accessory for most woodworking tasks, particularly those that require precision. It ensures safer and higher-quality cuts in a wide range of materials. The idea behind it is to create a snug fit between the blade and the throat plate, eliminating any undesired gaps or unevenness in cut depth.

In essence, a ZCI replaces the standard throat plate from your table saw with one that's cut precisely to match the shape of your saw’s blade. This helps keep chips from getting lodged in any open space around the blade, allowing them to freely fall away while ensuring a much cleaner cutline.

Beyond safety considerations, investing in these inserts can also help increase accuracy when working with finer materials like veneer or plywood; as they allow you to control stock thickness right at your saw table’s surface level rather than relying on additional jigs or templates set further away on your workbench—saving time and improving consistency throughout project builds!

Ultimately investing in an appropriately-sized zero clearance insert can be one of the greatest assets you bring into every woodworking project while yielding significant rewards shortly after installation. Not only does it provide smoother operation during use by reducing vibrations near fragile material but it also significantly adds more value across each job site through improved safety standards — making sure no one ends up hurting themselves during work!

2. How do you make a zero clearance insert for your table saw?

Answer: Making a zero clearance insert for your table saw is not as difficult as it might seem. All you need are a few simple tools and some patience.

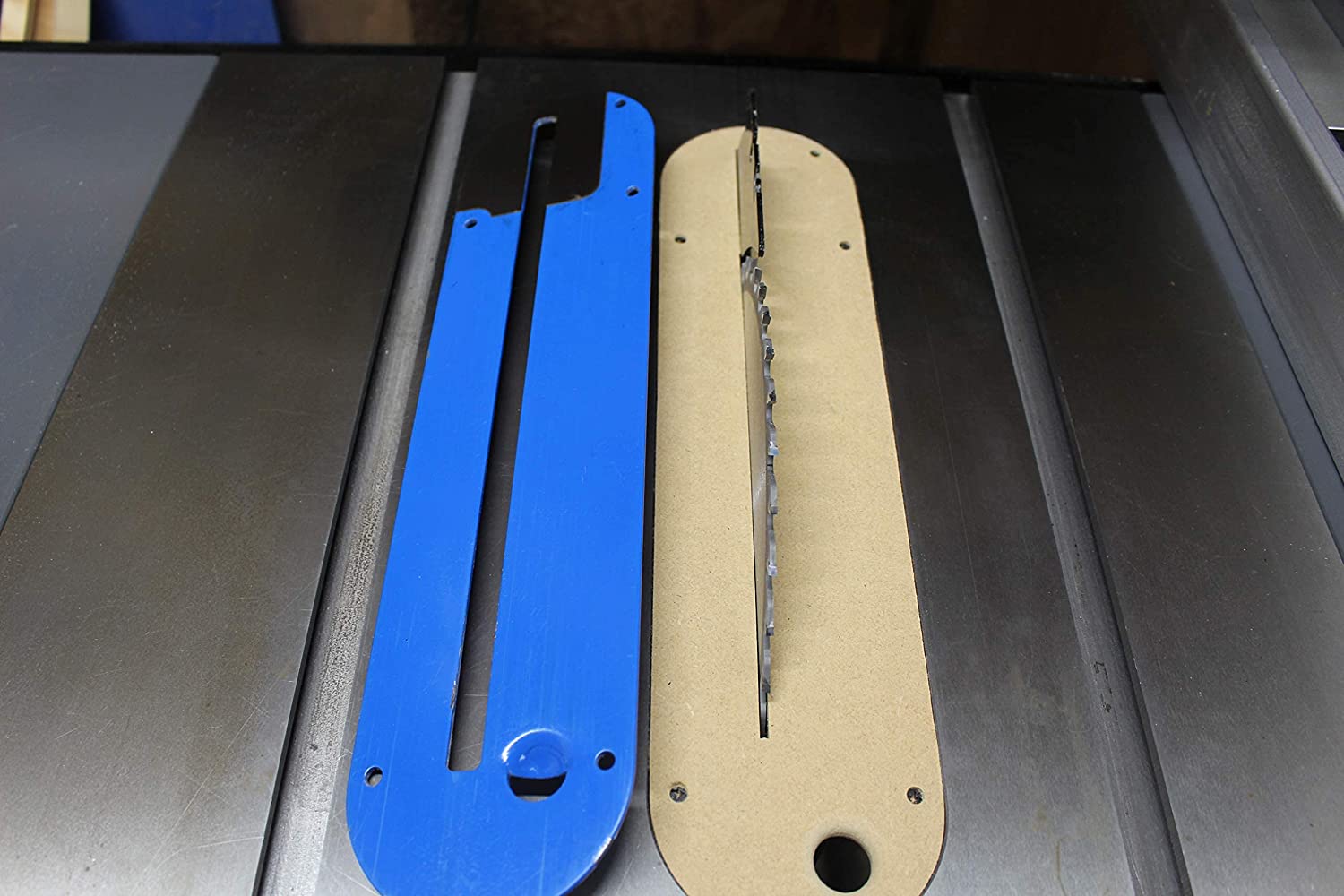

First, choose the material for your insert. A good choice would be plywood or plastic laminate, although hardboard or particle board will also work quite well. Make sure that whatever you choose can handle being cut with a table saw and does not flex too much when pressure is applied to it.

Next, measure the size of the gap in your tabletop where the blade passes through and draw an outline of that on the material from Step 1 with any sort of marker or pencil. To ensure precise cuts while making this new insert (known as tracing), clamping down on both sides of the material is beneficial, especially if using harder materials such as hardboard or particle board since they can easily warp under finger pressure alone due to their thin layers. Use a jigsaw to delicately follow through the marked line so that end result has precisely cut edges all around its perimeter; this will guarantee that there won't be any gaps once inserted into its designated slot in your table saw's top surface between two pieces of wood left behind by gone blades after multiple usage intervals over time which results in an unsafe working environment situation at times thus reducing chances of getting serious injuries while using table saw altogether--proposed by occupational safety experts following research data collected on 3666 participants over 16 years period globally). Afterward, carefully use sandpaper along every edged corner until it matches perfectly with existing tabletop corners/edge radius before finally placing onto its designated spot within table-top achieving aforementioned goal--i e having zero access insertion without leaving safety hazard risks behind like kicking off dust particles towards operator's face due to friction created between cutting object & blade resulting in potential harm caused whereas this new solution eliminates those very concerns provided taken into account mentioned steps throughout process!

3. How can a zero clearance insert improve your table saw experience?

Answer: A zero clearance insert is one of the most important and cost-effective upgrades you can make to your table saw. It helps reduce tear out, resulting in cleaner and more precise cuts. Additionally, it prevents kickback from occurring when making shallow cuts near the end of a board.

These inserts are made by cutting an opening in a thin piece of plywood or luan that fits snugly against the throat plate on a table saw. That way, as soon as you start cutting, there’s already zero gap between the blade area and the wood being cut – hence “zero clearance”. This results in improved accuracy because any width change due to blade movement won’t affect how much room is available around the blade itself.

Moreover, with zero clearance inserts you get better dust collection performance since chips are directed right into your dust extraction system instead of spraying up over your work space with each cut or getting stuck inside your throat plate while widening grooves for splintering boards further down stream.

Above all else though, using a zero clearance insert gives peace of mind knowing that dangerous kickbacks are less likely to occur during operation which makes any individual job site (and job) safer overall as well as enhancing user confidence no matter what kind of material is being worked with at any given time!

4. Are there any other benefits to using a zero clearance insert?

Answer: Absolutely! Using a zero clearance insert can provide many benefits beyond just making your cut safer, such as better precision and accuracy, improved productivity, and lower maintenance costs.

First, when you use a zero clearance insert on your saw blade it creates a perfect fit for the blade within the saw table which eliminates all looseness or wobble. This tight fit allows for more precise cuts that are more accurately aligned with the edge of your wood project. Not only do you get an improved finish but because there is less drift when cutting it also speeds up production time compared to using one without a zero clearance insert.

Another benefit to using this type of insert is that it reduces tear-out along the grain lines and makes cleaner cuts which leads to significantly fewer sanding or finishing steps later in projects. With less friction while cutting there’s also less wear-and-tear on expensive blades meaning they last longer giving you not only cost savings over time but allowing you to spend more crucial hours on other tasks instead of having to continuously replace dulled blades due to heavy usage and excessive heat build up from friction on materials like hardwoods or melamine surfaces.

Lastly, since these inserts are made from thin materials such as high-density plastics they don't change their shape even under extreme temperatures so they’re also very reliable in terms of repeatability across multiple cuts because their flatness doesn't warp or expand outwards over time like other thicker metal inserts do; this results in greater consistency across different types of cuts resulting in much smoother end products that require minimal effort spent polishing them afterwards.

5. Can you use a zero clearance insert with every table saw?

Answer: Yes - a zero clearance insert is designed to provide a precise fit for any table saw. This helps reduce the risk of kickback and offers superior accuracy for cutting, making it one of the most useful accessories for any DIYer or professional woodworker.

It’s advantageous to have a separate zero clearance insert dedicated to each blade size you use. That way, you can quickly switch between different blades without having to re-adjust your zero clearance insert with every change. Additionally, it also helps protect both the blade and throat plate from wear and tear due to chipping or burning caused by high friction when cutting materials like hardwood or plywood.

When installing a new zero clearance insert make sure it sits firmly in place so that there is no gap between it and your saw’s surface while also ensuring contact with both edges of the blade guard before powering up your saw again – this added safety measure will guarantee optimal performance as well as an increased lifespan for both you and your tools!