Installing a zero clearance insert for your DEWALT miter saw is an easy, straightforward process that will save you time and effort in the long run. Not only does it provide a clean, finished look to your cuts, but it also prevents any debris from getting into your machine and ruining the blades. Read on to learn how to install one of these inserts in just a few simple steps.

What You’ll Need

Before you begin this project, make sure you have all the necessary materials on-hand. The first thing you’ll need is the zero clearance insert itself; there are several models available depending on which type of miter saw you have. Additionally, you’ll need a Phillips head screwdriver or drill bit and some screws (these should come with the insert). Finally, make sure to have some wood glue handy; this will help keep the insert in place once it is installed.

Installation Instructions

Once you have all the necessary supplies, it's time to install your new zero clearance insert! Begin by removing any existing inserts from your miter saw; these can be removed easily with a Phillips head screwdriver or drill bit. Next, take your new zero clearance insert and position it inside the saw blade opening. It should fit snugly into place; if not, use wood glue to hold it in place. Once secure, take your screws and attach the inserts firmly to the base of the miter saw. Be careful not to overtighten them - this could damage both the insert and your machine.

Finally,

make sure that everything is properly aligned before beginning work - you don't want any unnecessary stress being put on either part! This will ensure that every cut you make is as precise as possible.

Conclusion:

Installing a zero clearance insert for your DEWALT miter saw may seem like an intimidating task at first glance - but with just a few simple steps and some patience, anyone can do it! Not only does installing one of these inserts provide better precision with each cut, but it also ensures that no debris will get into your machine and potentially damage blades or other important parts over time. With this tutorial in hand, now anyone can easily install their own DEWALT miter saw zero clearance insert!

A little story from John:

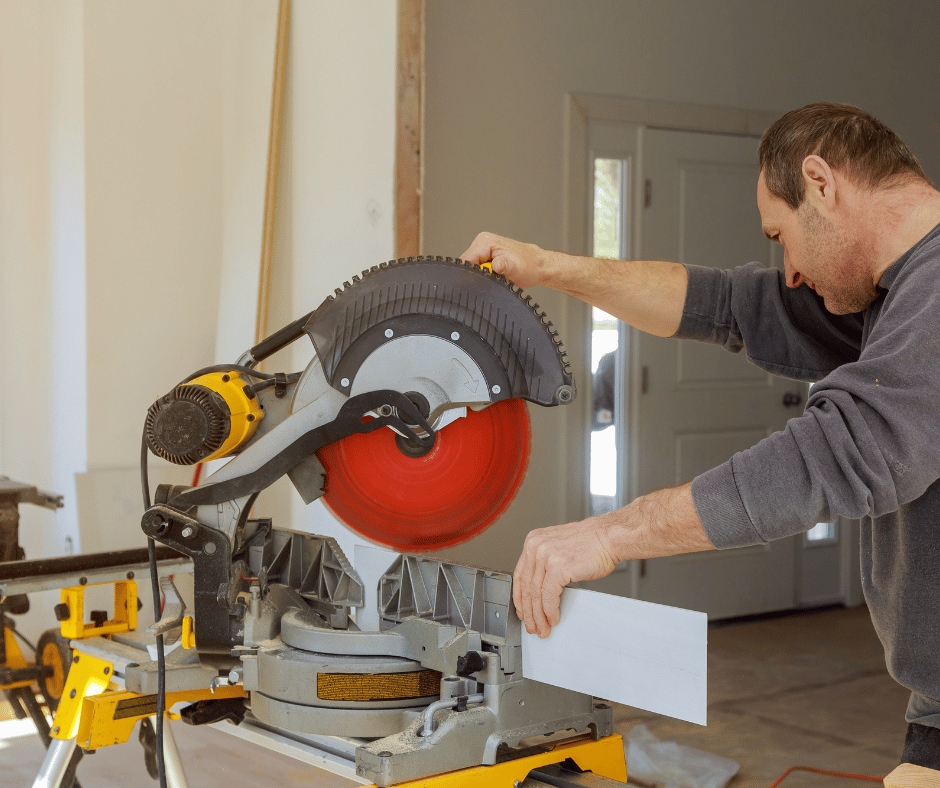

John had been doing some home renovation projects lately, and he was determined to do them himself. He had already finished painting the bedroom walls, replacing the bathroom sink faucet, and laying down new flooring in the kitchen. Now it was time to tackle his latest challenge: installing a Zero Clearance Insert for his DEWALT Miter Saw.

He knew this project could be complicated if he wasn’t careful, so he got out all of his tools and materials before getting started. After double-checking that everything was ready to go, John began by loosening the four screws on either side of the miter saw blade guard with a hex key wrench. With those removed, he carefully pulled up on the guard to reveal two mounting posts underneath.

Next came measuring – using a ruler or tape measure – from each post and marking off a point 1/8 inch away from where they met at their center point; this would ensure that there were no gaps between where the insert would fit once installed. Once marked off correctly, John used an awl or punch tool to make small holes in each of these spots for easy locating later on when attaching screws into place.

With that complete, it was time for installation! Taking hold of one end of the newly acquired zero clearance insert (which should fit snugly around both mounting posts), John screwed it into place using short woodworking screws; making sure not to over tighten them as this could cause warping in both sides of the insert itself! When all four were securely fastened into position using a screwdriver bit head drive bit setter toolset specifically designed for woodworking projects like this one – voila!, John now had successfully installed his own Zero Clearance Insert for use with his DEWALT Miter Saw!

Feeling proud about what he just accomplished - despite its complexity - gave him motivation towards tackling more complex DIY projects in future days ahead!