You've probably heard of boring bars, but we bet you didn't know they had sleeves! That's right– boring bar sleeves are a real thing, and they're actually way more exciting than they sound. Whether you're a machinist or an industrial engineer, you'll definitely want to keep reading to find out why boring bar sleeves are not so boring after all.

1. They Come in Various Types --Boring bar sleeves come in two different types:

solid and split. Solid boring bars are used when the workpiece is too large to be mounted on a standard-sized lathe chuck. Split boring bars can fit into tight spaces, making them ideal for working with small components such as motor mountings or engine blocks.

2. They Can Be Used With Any Kind of Lathe

--Boring bar sleeves can be used with any kind of lathe, including manual, CNC or specialized machines that are designed specifically for use with boring bars. This makes them incredibly versatile and gives machinists the flexibility to work with a variety of materials and components.

3. They Make it Easier to Achieve Perfectly Round Holes

--When it comes to drilling holes in metal, accuracy is key. Boring bar sleeves make it easier for machinists to achieve perfectly round holes without having to worry about inconsistencies in shape or size.

4. They Last Longer Than Standard Drill Bits

--Standard drill bits tend to wear down quickly, especially when used on hard metals like steel or aluminum. The durable construction of boring bar sleeves ensures that they last much longer than standard drill bits and can handle even the toughest jobs without breaking down prematurely.

5. They Can Handle Tough Materials

– Boring bars are designed for cutting through tough materials such as steel, aluminum, brass and titanium with ease. By utilizing the right type of tooling and lubricant, machinists can rely on their boring bar sleeve to get the job done quickly and accurately every time!

6 .They Allow For More Precise Drilling

– With its slim design and adjustable length, a boring bar sleeve allows for much more precise drilling than a standard drill bit ever could– even when dealing with complex shapes or tiny components!

7 .They Reduce Vibration

– Thanks to their unique design and construction, boring bar sleeves reduce vibration while drilling– making them safer for both the operator and the machine itself!

8 .They Require Less Maintenance

– Unlike their standard drill bit counterparts which require frequent sharpening or replacement due to wear-and-tear from continuous use–boring bar sleeves require little maintenance beyond occasional cleaning after use!

Φ10 mm SHB25‑10 Carbide Boring Bar Lathe, Boring Bar Holders Sleeve Turning Tool Holder Strip

Why We Love It:

The 10mm SHB25-10 Carbide Boring Bar Lathe Boring Bar Holders Sleeve Turning Tool is perfect for any CNC project! It is made with tungsten steel for extreme durability and strength. The turning tool has continuous and stable holding force and offers stable operation and high precision. It is also lightweight and easy to carry, making it great for any project.

What You Should Know:

The SHB25-10 boring bar holder sleeve tool has a fine workmanship and is compatible with most CNC machines. It has an outer diameter of 25mm/0.98in and a clamping boring tool diameter of 10mm/0.4in. This tool is perfect for a variety of CNC projects, making it the perfect choice for any CNC enthusiast. Plus, it's easy to store and use, so why wait? Get your own 10mm SHB25-10 Carbide Boring Bar Lathe Boring Bar Holders Sleeve Turning Tool today!

SBHA20-25 CNC Lathe Inner Diameter Auxiliary Stable Tool Holder Inner Hole Boring Tool Sleeve for Straight Shank Tool Inner Diameter Turning Tool Bar

Why We Love It:

The SBHA20-25 CNC Lathe Inner Diameter Auxiliary Stable Tool Holder is an essential part of tool placement on the CNC lathe. It improves tool rigidity and extends tool life, as it automatically centers the height more accurately.

It can fix the center of the tool, saving the trouble of traditional gasket searching, and it also helps to increase stability, avoid the fracture of carbide tool bar, and improve tool feed speed and cutting amount.

What Else Should You Know:

The SBHA20-25 CNC Lathe Inner Diameter Auxiliary Stable Tool Holder is easy to install, remove, adjust, and repair. It can be used to install straight shank tools, inner diameter turning tool bars, twist drills, U drills, extension rods, turning tools, boring tools, center drills, and more.

This tool holder can be used in a wide range of CNC lathe applications and is perfect for any CNC lathe user. Get yours today and take your CNC lathe operations to the next level!

Turning Tool Sleeve CNC Parts Boring Bar Holder

Why We Love It:

If you're looking for a reliable and durable turning tool sleeve, then the SHB20 HSS for Milling Machines for CNC is the perfect choice! This high-quality product is made of high-speed steel which has been through high temperature quenching, to ensure that it has excellent hardness, wear resistance, fatigue strength and toughness. Plus, the surface has been treated with vacuum nitriding to make it even more wear resistant.

What You Should Know:

The SHB20 HSS for Milling Machines for CNC is a must-have for any CNC machine, as it is compatible with a variety of machines. All of its working parts are precision ground and hardened for maximum durability. Plus, it also features a bright surface for easy identification. So, why wait? Get your Turning Tool Sleeve CNC Parts Boring Bar Holder today!

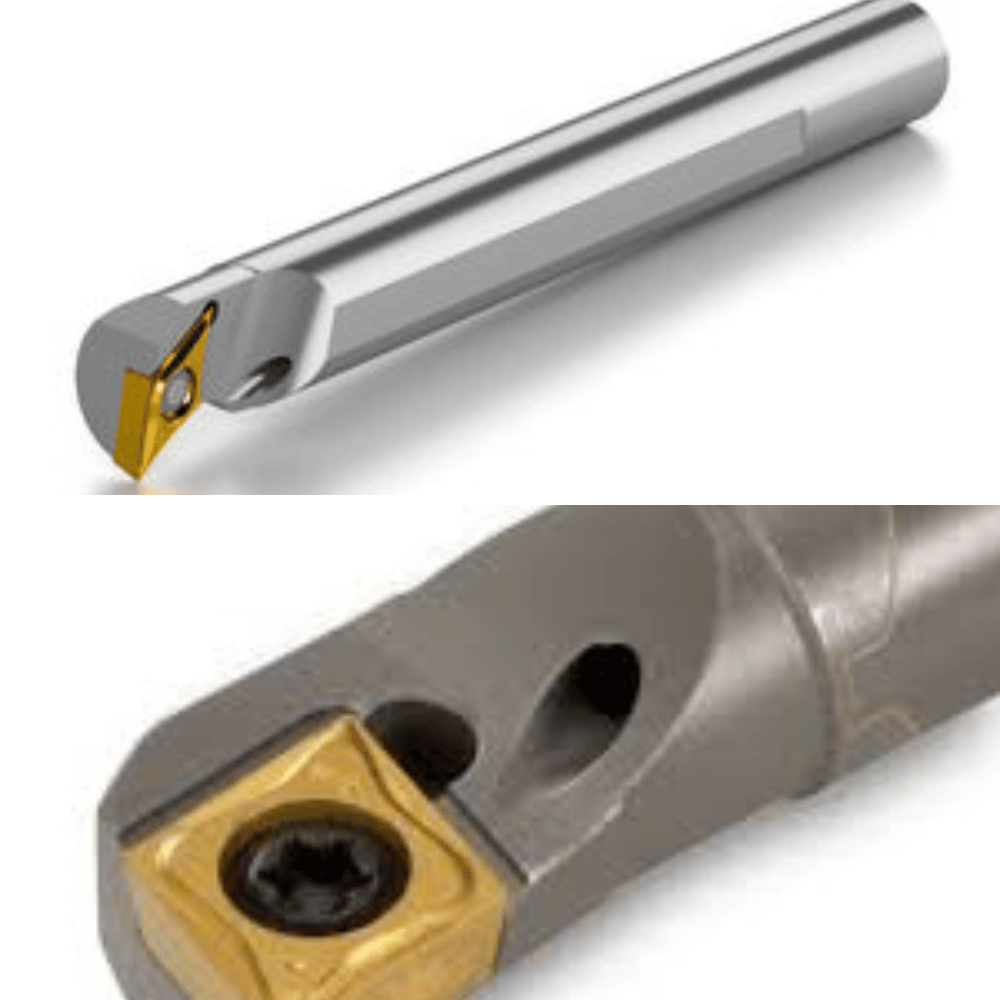

Indexable Boring Bar Set

Why We Love It:

Accusize Industrial Tools Sclcr 4 Pc Indexable Boring Bar Set is perfect for those who are in need of a reliable and precise indexable boring bar set. This set includes four indexable boring bars (1/2'', 5/8", 3/4'' and 1"), 14 Carbide CVD coated CCMT 32.5 black-and-white Inserts, one torx wrench, and one fitted case.

The inserts are securely held with a torx screw to reduce tool slipping, while the bar has a hardness of approximately 45HRC to ensure optimal performance. Plus, this set is characterized by an extreme gloss finish, making it the perfect choice for professional applications.

What You Should Know:

Accusize Industrial Tools Sclcr 4 Pc Indexable Boring Bar Set is the perfect choice for anyone who needs a reliable and precise indexable boring bar set. Thanks to its negative 5° end side cutting angle and high-quality construction, you can be sure that this set will deliver precision and accuracy every time.

Plus, the torx wrench and fitted case make it easy to store and transport. So why wait? Get your own Accusize Industrial Tools Sclcr 4 Pc Indexable Boring Bar Set today!

Product Description

Accusize - SCLCR 4 Pc Indexable Boring Bar Set, P252-S416:

Features:

- Extreme Gloss Finish

- Utilizes 80° Diamond CCMT inserts

- Negative 5° End side cutting angle

- Bar hardness approx. 45HRC

- The insert is securely held with a torx screw to reduce tool slipping

- Includes:

- 4 Indexable boring bars (each boring bar has 1 insert installed)

- 1 each of 1/2'', 5/8", 3/4'' and 1"

- 10 Carbide CVD Coated CCMT 32.5 black-and-white Inserts

- 1 - Torx Wrench

- 1 - Fitted Case

Features of chipbreaker:

- For medium-duty turning With broad capability for steel, stainless steel, grey and nodular cast-iron

- Operations: turning, facing and profiling

- Advantages: all-round, reliable with problem-free machining

- Limitations: depth of cut and feed, risk of overloading the cutting edge

- Components typically: axles, shafts, hubs, gears, etc.

FAQs

1.Have you ever been confused about the purpose of a boring bar?

A boring bar is a tool used in machining to enlarge existing holes or create new ones, but it can be hard to know exactly how it works. You might be wondering what the different types of boring bars are, how to use them, and which one is the right choice for your project.

We've compiled a list of the most frequently asked questions about boring bars so you can get the answers you need and make the best decision for your project.

2. How do you balance a boring bar?

Balancing a boring bar involves making sure that the cutting edge of the bar is parallel to the axis of the workpiece. To achieve this, you need to adjust the angles of the tool holders and the cutting edge of the bar.

This is done by measuring the distance between the cutting edge and the workpiece, and then adjusting the tool holders and the cutting edge of the bar until the distance is equal on both sides. This will ensure that the cutting edge is parallel to the axis of the workpiece.

3. How do you align a boring bar?

Aligning a boring bar requires making sure the bar is parallel to the bore axis. This can be done by measuring the distance from the bore axis to the cutting edge of the bar at various points along the bar.

If the measurements are not equal, then the bar is not parallel to the bore axis and must be adjusted. Adjustments can be made by loosening the set screws that hold the boring bar in place and then carefully adjusting the bar until the measurements are equal. Once the bar is aligned, the set screws should be tightened to ensure that the bar remains in place.

4. Is a boring bar accurate?

Yes, a boring bar is an accurate tool. It is used to precisely measure the inner diameter of a hole or bore. The boring bar is designed to provide a consistent and accurate measurement, as it is equipped with a dial indicator that is used to measure the diameter. The boring bar can also be used to measure the depth of a hole or bore.

5. How do I stop my bar chatter from boring?

The key to stopping bar chatter from becoming boring is to be creative and engaging. Ask interesting questions, start conversations about topics that are relevant to the group, and use humor to lighten the mood.

Additionally, try to avoid talking about topics that are too controversial or divisive, and focus instead on topics that will bring everyone together. Finally, don't be afraid to pause and listen to what others have to say, as this will help keep conversations interesting and give everyone a chance to contribute.

6. What angle does a boring bar cut?

A boring bar is a cutting tool used to enlarge existing holes in a workpiece. The angle of the cut depends on the type of boring bar being used. Generally, the angle is between 90 and 120 degrees, with a 90-degree angle being the most common.

7. What are the maintenance of boring tools?

The maintenance of boring tools involves regular cleaning, sharpening, lubrication, and inspection. Cleaning should be done after every use to remove any debris or dirt that may have accumulated on the tool.

Sharpening should be done periodically to ensure the cutting edges remain sharp and can make accurate cuts. Lubrication should be done to reduce friction and wear on the tool and to prevent rusting. Finally, inspection should be done to check for any wear or damage that may have occurred and to ensure the tool is still in good working condition.

8. What are the three most important factors for successful fine boring?

The three most important factors for successful fine boring are tool selection, proper cutting parameters and machine rigidity. Tool selection includes choosing the right type of boring bar and cutting tool for the job. Proper cutting parameters include selecting the right feed rate, spindle speed and cutting depth. Lastly, machine rigidity is important to ensure a consistent cut and to minimize vibration.

9. What are the rules of boring?

The rules of boring are a set of guidelines to help you avoid being boring in conversations and other activities. These rules include:

1. Be engaged in the conversation—ask questions and show genuine interest in what the other person is saying.

2. Don’t be afraid to take risks—try something new or offer an opinion that might be controversial.

3. Don’t be afraid to be wrong—it’s okay to make mistakes and learn from them.

4. Be honest—don’t be afraid to express your true feelings and opinions.

5. Be creative—think outside the box and come up with new ideas.

6. Be open-minded—listen to other people’s ideas and be willing to consider them.

7. Have fun—take time to enjoy yourself and have a good time.

10. What are the disadvantages of boring machine?

The primary disadvantage of a boring machine is that it can be difficult to set up and use for precise operations. Boring machines require a high level of skill and experience to use effectively, and even minor mistakes can lead to a poor quality finish or inaccurate results. Additionally, boring machines are often expensive to purchase and require a lot of maintenance to keep them in good working order. Finally, boring machines are not suitable for all types of materials, and may not be able to process some materials that require more specialized machinery.

11. What is the purpose of a boring bar?

A boring bar is a tool used in machining operations to enlarge existing holes in a workpiece. It is typically used in lathes and mills, and is usually attached to a boring head. The boring bar is inserted into the hole and rotated while the cutting head is fed into the hole, gradually enlarging it to the desired size. Boring bars are typically made of high-grade steel and are designed to produce precise, accurate results.

Conclusion:

Who knew that something called "boring" could be so interesting? From their various types available through their ability to handle tough materials; there's no denying that boring bar sleeves have some pretty impressive capabilities!

So next time your project calls for precision drilling; don't forget about these handy tools—they may just save your day (or at least make it easier). With this newfound knowledge of why boring bar sleeves aren't so “boring” after all you'll be sure to take advantage of their many benefits!

And if you ever need help choosing the right type of tooling or lubricant—give us a call; we'd be happy to help out!

We hope this article has helped you understand what a boring bar is and why it’s such an important tool for machining operations. From drilling to reaming and tapping, boring bars are designed to provide precision and accuracy for all your drilling needs.

With their wide range of sizes and features, these tools are sure to meet all your machining requirements. So don’t wait any longer and choose the boring bar that’s right for you – you’ll be glad you did!