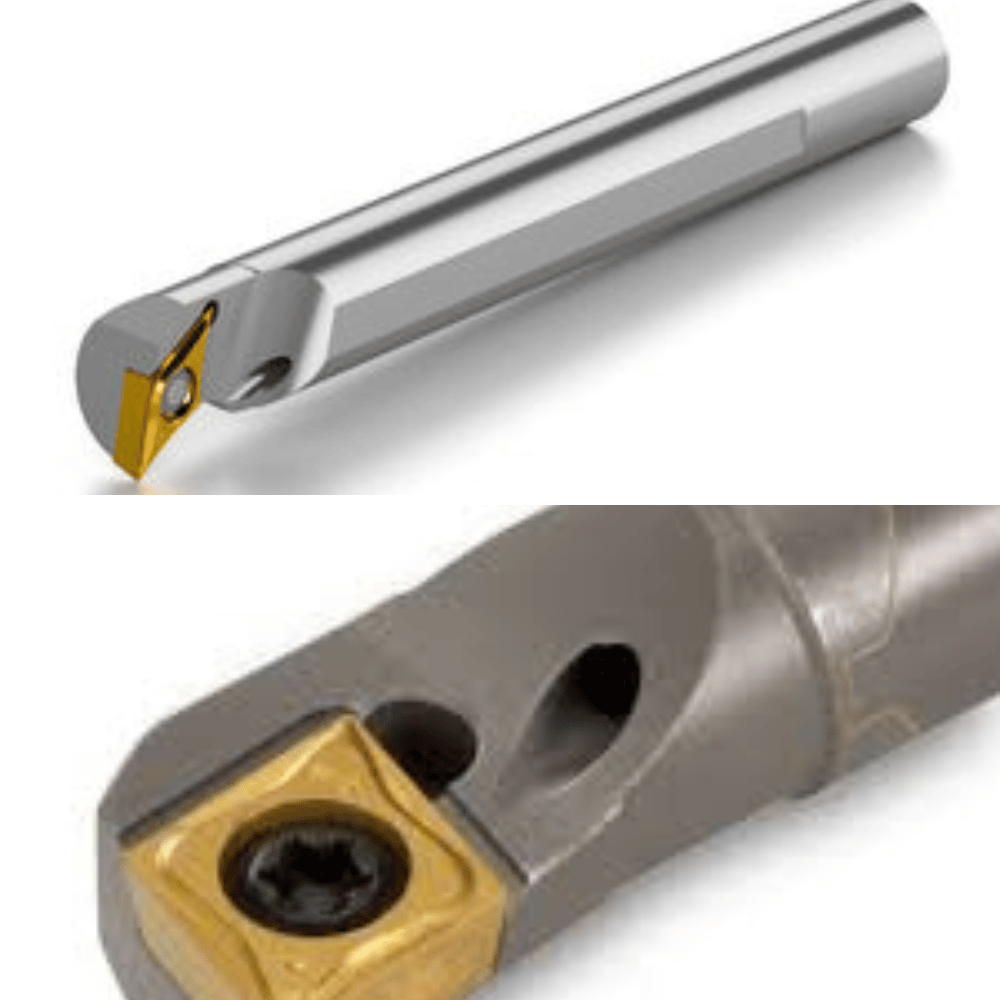

If you're a machinist, then you know how important it is to have the right tools for the job. From drill bits to taps and dies, having the right equipment makes all the difference. One tool that should always be in your arsenal is a carbide boring bar. Here are five reasons why you need carbide boring bars in your life.

1. Precision Drilling - Carbide boring bars are designed specifically to provide precision drilling. This means that when you're working on a project, you can use a carbide boring bar to precisely control where and how far you drill into something without worrying about over-drilling or ruining your workpiece.

2. Increased Durability - Carbide boring bars are made of hardened steel and tungsten carbide, making them incredibly durable and long-lasting compared to other types of cutting tools like high-speed steel drills or regular drill bits. This means that even after years of use, your carbide boring bar will still be just as sharp and accurate as it was when you first purchased it!

3. Versatility - Carbide boring bars can be used for a variety of applications such as drilling holes in metal, plastic, wood, and other materials with ease and accuracy. They also come in different sizes so that they can accommodate various projects from small-scale hobbyists to large industrial operations.

4. Cost Efficiency - In addition to being versatile and durable, carbide boring bars are also cost effective compared to other types of cutting tools because they require less maintenance over time due to their durability and longevity. This saves money on having to replace worn out or broken tools constantly!

5. Time Efficiency - Finally, using a carbide boring bar will save you time because it doesn't require any additional setup or preparation before use unlike some other types of cutting tools which may require additional steps such as sharpening before use or frequent maintenance over time due to wear and tear on the tool itself.

Conclusion: Whether you’re a professional machinist or an amateur hobbyist looking for precision drilling results every time, carbide boring bars are the perfect choice for getting the job done quickly and accurately every single time! They’re versatile enough for a variety of tasks, cost efficient in terms of maintenance needs over time, durable enough for repeated uses without losing their edge quickly like some other cutting tools might do – what more could you ask for? Get yourself a carbide boring bar today if precision drilling is part of your daily routine!

How We Choose

Boring bars are essential tools for machinists looking to create precise and accurate holes. But with so many different types of boring bars available, it can be hard to know which ones will give you the best results.

Our team of experts has done all the research for you so that you can easily find and purchase the perfect carbide boring bar for your needs. We've read thousands of reviews on Amazon to determine which one offers the best value for your money and delivers superior performance.

No more guesswork or wasted time trying to figure out what works best - just the perfect carbide boring bar that is sure to make a difference in your projects! Check out our reviews today and get ready to take your machining skills up a notch!

Accusize Industrial Tools 5/8" 9 Pieces/Set, Indexable Carbide Turning Tools and Boring Bar,

Why We Love It:

The Accusize Industrial Tools 5/8" 9 Pieces/Set Indexable Carbide Turning Tools and Boring Bar is a great solution for machinists looking to finish multiple lathe operations. This complete set comes with 9 pieces of indexable lathe tooling that is designed for lathes with 6" to 15" swing over bed.

The smooth finish on each turning tool holder makes for easy identification, and each tool holder comes with a C6 TiN Coated carbide insert with positive rake cutting angle and built-in chip breaker. Plus, the set comes with insert screw and wrench, hex screw, hexagon key, and an aluminum fitting case.

What Else Should People Know:

Accusize Industrial Tools 5/8" 9 Pieces/Set Indexable Carbide Turning Tools and Boring Bar is the perfect solution for any machinist looking to take their lathe operations to the next level. This complete set is easy to use and comes with all the necessary accessories needed to make the most out of your lathe.

The set includes 9 pieces of indexable lathe tooling, insert screw and wrench, hex screw, hexagon key, and an aluminum fitting case. Plus, the inserts are C6 TiN Coated carbide inserts with positive rake cutting angle and built-in chip breaker, making them perfect for general purpose cutting action.

If you're looking to upgrade your lathe operations, Accusize Industrial Tools 5/8" 9 Pieces/Set Indexable Carbide Turning Tools and Boring Bar is the perfect choice!

Boring Bar Set,VerRich 4pcs Lathe Boring Bar

Why We Love It:

The VerRich Boring Bar Set is a must-have for all machinists who need a reliable and durable tool to get the job done. This set includes 4 bars made from high-quality steel, 10 CCMT0602 inserts, and 4 wrenches.

The main part of the bar is imported and the 40Cr material ensures that it is durable and long-lasting. The 95-degree lead cutting angle, right-hand direction, and clear marks on the wrench make it easy to identify the bar holders, so you don't waste time trying to figure out which one to use.

What You Should Know:

The VerRich Boring Bar Set is an excellent tool for those who need to work in small spaces or tight areas. It is perfect for machining small holes and features a simple and tightly impacted bolt structure.

Plus, VerRich offers a 1-year quality warranty, so you can be sure that it is dependable and reliable. So why wait? Get your own VerRich Boring Bar Set today and enjoy the convenience and durability it provides!

FAQs

Finding the right carbide boring bar can be a challenge, especially when there are so many different brands and types on the market. It's important to find a bar that offers the best performance and reliability, but it can be hard to know which ones have the features you need.

We've compiled a list of the most frequently asked questions about carbide boring bars so you can make an informed decision and get the best value for your money.

How do I stop my boring bar from chattering?

Chattering is usually caused by a dull cutting edge, so the first thing you should do is check the sharpness of your bar. If it is dull, you should sharpen it. If the bar is already sharp, then you may need to adjust the tension of the chain. The tension should be tight enough that the chain does not slip, but not too tight that it puts too much pressure on the bar. You can also try using a different type of chain, as some chains are better suited for certain types of bars.

2. When selecting a boring bar you should select?

When selecting a boring bar, you should consider the material that you will be boring, the size of the hole you need to bore, and the type of boring bar you need.

For example, if you are boring a large hole into a soft material such as aluminum, then a solid carbide boring bar would be a good choice. If you are boring a smaller hole into a harder material such as steel, then a diamond-coated or carbide-tipped boring bar would be a better choice.

Additionally, you should consider the type of cutting edge that you need, as well as the type of shank that you need for your boring bar.

3. How do you balance a boring bar?

Balancing a boring bar involves setting the tool so that it is perpendicular to the workpiece and parallel to the spindle axis. This ensures that the tool will make an even cut across the entire surface of the workpiece. To do this, you will need to adjust the tool holder, the boring bar, and the cutting tool. You should also use a dial indicator to measure the depth of the cut and adjust the tool accordingly.

4. How do you align a boring bar?

Aligning a boring bar is a process that involves making sure the bar is centered in the bore and that the cutting edge is parallel to the bore walls. The first step is to mount the boring bar in the machine spindle and make sure it is centered. Then, the bar should be adjusted to the correct height and angle so that the cutting edge is perpendicular to the bore walls. Finally, the bar should be checked with a dial indicator to ensure that it is aligned correctly.

5. How do I stop my boring bar tool from vibrating?

The most common cause of a vibrating bar tool is an imbalance in the cutting blades. To stop the vibration, you should check the blades to make sure they are properly aligned and balanced. You can also check the bearings for any signs of wear or damage. If the bearings are worn or damaged, they should be replaced. Additionally, you can adjust the tension of the blade drive belt to reduce vibrations. Finally, make sure the tool is properly mounted on a stable surface.

6. What causes chatter in boring?

Chatter in boring is typically caused by excessive vibration of the cutting tool. The vibration can be caused by a number of factors including poor tool design, poor machine setup, poor tool sharpening, or incorrect cutting parameters. It is important to identify the cause of the chatter in order to correct the problem. Some possible solutions include using a different tool design, adjusting the machine setup or cutting parameters, or sharpening the tool with a different grinding wheel.

7. What are the three most important factors for successful fine boring?

The three most important factors for successful fine boring are the selection of the right tool, the proper setup of the tool, and the correct cutting parameters. When selecting the tool, it is important to choose a tool that is designed for the material being machined and the type of finish desired.

The setup of the tool should consider the cutting geometry, the cutting speed, and the amount of coolant being used. Finally, the cutting parameters should be adjusted to optimize the cutting process for the material being machined, the type of finish desired, and the cutting speed.

8. What angle does a boring bar cut?

Boring bars are used to create internal cylindrical shapes, such as holes and bores. The angle of the cut depends on the type of boring bar being used. Generally, a boring bar will cut at an angle of 90 degrees, but some may cut at an angle of up to 120 degrees. Additionally, the angle of the cut may also depend on the type of material being cut and the size of the hole being created.

9. What are the maintenance of boring tools?

The maintenance of boring tools involves a few different steps. First, it is important to inspect the tool for any visible signs of wear or damage. If any damage is found, the tool should be replaced. Next, it is important to regularly clean the tool to remove any debris or buildup that could cause it to malfunction.

Additionally, it is important to lubricate the tool regularly to ensure that it moves freely and does not become stuck. Finally, it is important to store the tool in a safe and secure place to prevent it from becoming damaged or lost.

Final Thoughts:

Carbide boring bars are the perfect tool for any machinist. Whether you need to make precision cuts or produce accurate, intricate shapes, these bars will provide the reliable performance you need. With their superior strength and heat resistance, they are sure to stand up to the toughest jobs.

So if you're looking for a reliable tool that will help you get the job done, then look no further than carbide boring bars! With the right bar in hand, you'll be ready to take on any challenge that comes your way.