When you’re tackling a DIY project, having the right tools is key. The Chicago Electric 10 Miter Saw is a reliable and powerful tool that can help you make precise cuts with ease. However, like any tool, it needs occasional maintenance to stay in good condition. One of the most common maintenance tasks is changing the saw blade. If you need to do this but aren’t sure where to start, keep reading for our beginner-friendly guide on how to replace the blade on your Chicago Electric 10 Miter Saw.

Replacing The Blade On Your Chicago Electric 10 Miter Saw

Before you begin replacing your saw blade, make sure you have all of the necessary materials on hand—you’ll need an adjustable wrench, a new blade (it should be compatible with your saw), and safety gear such as work gloves and safety glasses. Once everything is ready to go, it’s time to get started!

First

The first step is to unplug your saw from the power source and remove any material that may still be attached to it.

Second

Then, use an adjustable wrench to loosen and then detach both bolts that hold the blade guard in place. This will allow you to access the saw blade itself – but remember not to touch it yet!

Third

Loosen and then remove both bolts that secure the saw blade itself using the same adjustable wrench.

Forth

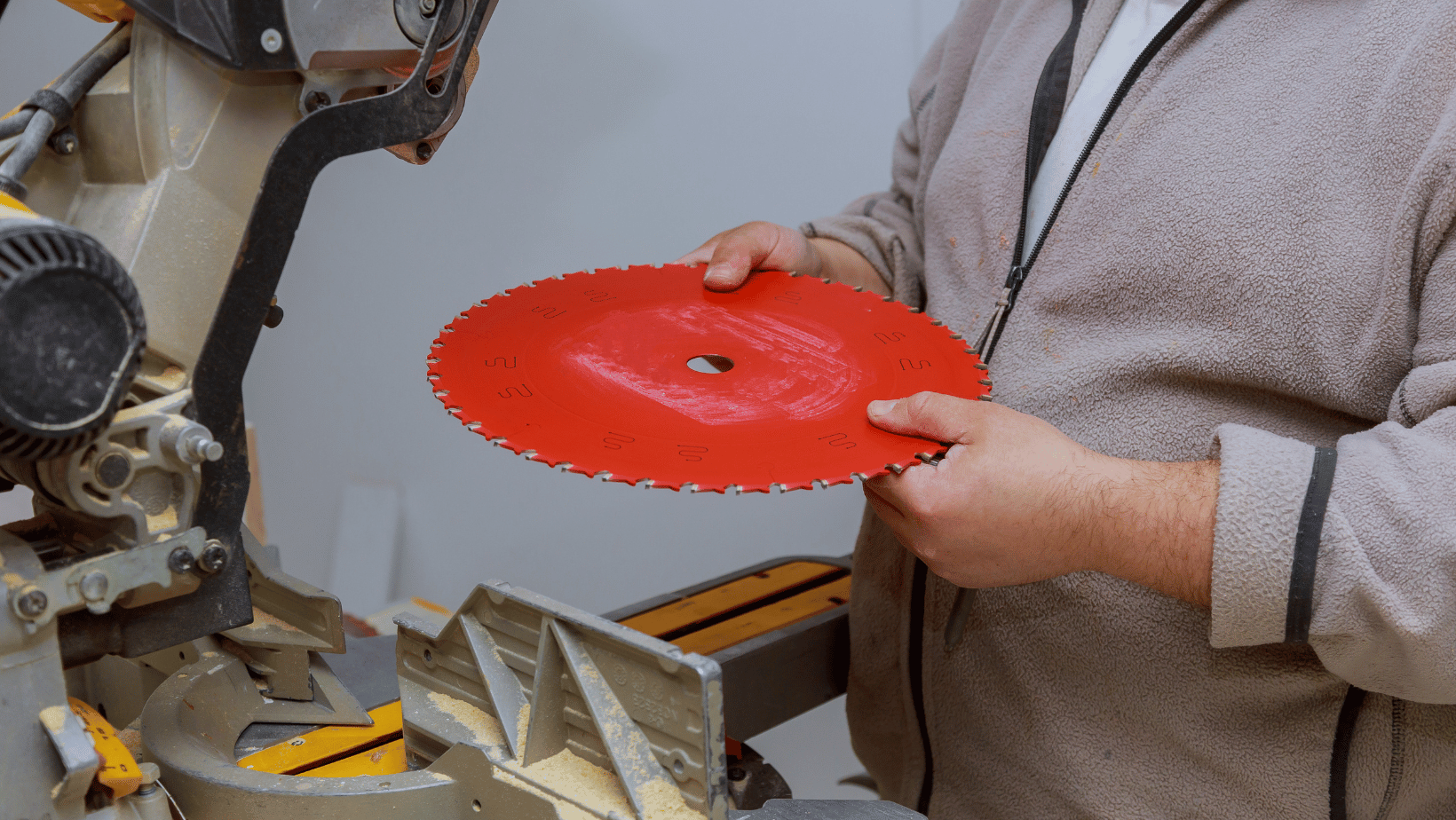

Carefully lift off the old blade – keeping in mind that it will still be sharp – and set aside.

Finally

Now comes one of the most important steps—installing your new saw blade!

Carefully slide it onto its mounting plate until it fits snugly into place (you shouldn’t have to force it). Put your safety gear back on before proceeding; even though your new saw blade isn’t exposed yet, always observe proper safety precautions when working with power tools like this one. Once you feel comfortable doing so, reattach both bolts that secure the blade guard in place and tighten them up using an adjustable wrench. Last but not least, plug your saw back into its power source and test out your newly replaced saw blade – making sure not to put any material into it just yet!

Final Thoughts:

We hope this beginner-friendly guide helps make replacing the blades on your Chicago Electric 10 Miter Saw easy and stress-free! Be sure to follow all safety precautions when changing or handling any type of power tool—your safety is paramount! If for some reason you find yourself stuck or unable to complete this task yourself, don't hesitate to contact a professional who can help finish up with ease. Happy DIYing!

FAQs

2. QUESTION: What type of saw blade do you use most often?

ANSWER: It depends a lot on what type of project I'm working on. For the most part, for cutting through metal (particularly thin sheet metal) I prefer to use a carbide-tipped blade. These blades are much sharper than standard steel blades and they last much longer, so you don't have to replace them as often.

However, if I'm using wood or plastics, it really depends on the thickness of the material and how fine a cut is required. In that case, my go-to blade is usually an ultra-thin kerf saw blade with several triple chip grind (TCG) teeth along its edge – this provides excellent control while still allowing me to make precise cuts quickly. This type of saw blade also works great when ripping long lengths of stock in one pass thanks to its sturdy construction and thicker gauge body which keeps it from flexing during operation.

Finally, when dealing with extremely hard woods like maple or oak or if I'm trying to make quick cuts in framing lumber for larger projects then I'll opt for a general purpose rip/crosscut combination style saw blade with alternate top bevel (ATB) teeth instead – these can handle tough materials easily without causing too much tear out at the edges but still offer enough speed that you can get tasks done quickly without sacrificing accuracy or quality.

No matter what kind of project you're tackling, investing in good quality saw blades is always worth your time and money since they'll help you produce better results faster while increasing their useful lifespan as well!

2. QUESTION: Why do you think changing the blade is important?

ANSWER: Changing the blade of a tool or device is important for many reasons. First and foremost, it ensures our tools are working at peak performance. Dull blades create more friction and require more effort to get the job done; new blades will slice through material easier and with less frustration.

Second, changing a blade regularly helps us stay safe while using our tools. As blades become dull, they can start to slip or jut out in odd directions when applying pressure. A fresh blade won't have these issues as it is not yet worn down from regular use. The last thing anyone needs is an injury due to faulty equipment like a worn out blade!

Finally, changing your blade also saves you money in the long run because you don't have to replace your entire tool as often. While buying replacement blades may be an upfront expense, checking them regularly and replacing them when needed is far cheaper than having to purchase an entirely new device because of some minor damage resulting from dull blades (especially if it was potentially avoidable).

While the importance of changing your tool’s blades may seem small relative to other tasks, I think we should all remember how significant this practice can be in ensuring safety and efficient work practices – both of which save time and money!

3. How can you tell when it's time to change the blade on your saw?

Knowing when to replace the blade on your saw is a key part of being a safe and efficient woodworker. When you use the wrong blade for the job, or an old and worn one, it can cause kickback which puts you at risk for injuries.

Here are some tell-tale signs that it's time to change your saw blade:

- Dullness – As blades age, they become increasingly dull as their edges wear down. Pay close attention to how well your cuts are coming out; if they're not as precise or clean as usual, then it may be time for a new blade.

- Uneven Teeth – Check the teeth of your blades from time to time; if they seem bent or uneven in any way, then they should be replaced before using the saw again. This will ensure safer cutting results with smoother edges and less vibration.

- Heat Buildup – If there's excessive heat buildup during operation (this is especially true of circular saws), then this could indicate that you need new blades due to them having been sharpened too much or used beyond their lifespan. It’s also important that you let your blades cool after each use in order to prevent overheating and damage over time.

- Cracks & Chips – Any signs of cracks or chips along the sides should prompt immediate replacement - these weaken the integrity of both material being cut and make it more difficult for controlling depth when making cuts into tough materials like hardwoods etc., thus increasing danger risk significantly!

- Warping & Unbalanced Blades - Over long periods of use (especially with harder materials such as steel alloys), some blades may become unbalanced due to warping from continuous impacts on material surface areas while cutting; unbalanced/warped blades create vibrations during operation which can lead not only to inaccurate cuts but also potentially hazardous situations!

Once these criteria are met when inspecting your various types of sawblades, go ahead and replace them before continuing work - always remember safety first!

4. Do you have any tips for those who are new to changing blades on a miter saw?

Congratulations on taking the plunge and getting yourself a miter saw! Changing the blade isn’t as daunting as it might seem, so don’t worry if you’re feeling a bit overwhelmed. Here are some tips to help make the process easier:

Choose the right replacement blade for your project: Make sure that your new blade is compatible with your model of miter saw, especially when it comes to diameter and number of teeth (numbers like 8-inch and 60-tooth). Additionally, read up on which type of blade would be best for cutting different materials (e.g., metal vs wood blades).

Unplug the power source before changing blades: Safety first! It is vital that you unplug the saw before making any changes to avoid potential electric shock hazards or accidental damage to either you or those around you.

Securely hold down both handles while loosening bolts: Loosening bolts can be tricky since they can become quite tight after repeated usage. Always use two hands to keep a firm grip on both handles while loosening each bolt one at a time in order avoid sharp movements or jolts that could throw off your balance or potentially cause injury due to slipping however needs be using pliers may help remove them easily too! If possible, place rags under each handle for extra grip if needed..

Place wood blocks underneath clamp while replacing blades: Before removing old blades from their holders, support them with wooden blocks beneath each clamp in order preserve their sharpness and accuracy during removal/installation - doing this will also eliminate any additional vibrations from happening during this step!. Once everything is in place, fasten all screws securely again by hand-tightening before tightening further with an adjustable wrench for added safety precautions. Finally check twice whether all components (clamps / bolts) are properly tightened prior resuming regular operations - remember safety always comes first!.

By following these steps carefully, changing out your miter saw blades should no longer feel like such an intimidating task! Best of luck and happy building 🙂

5. What are some of the challenges that come with changing blades on a miter saw?

Changing blades on a miter saw can be an intimidating task for new woodworkers, but it doesn't have to be! Just like with any other tool in your shop, understanding the basics and taking safety precautions will help ensure a successful blade change.

The most important step when changing the blade of your miter saw is to unplug it from its power source before beginning work. This ensures that no one accidentally turns the machine on while you are operating on it.

Next, you'll need to remove the existing blade by loosening its fixing bolts/screws; these should be located around or near where the blade meets the motor shaft. Some miter saws use an arbor nut or bolt system, while others use a pin-type lock system - so check your user manual first if you aren't sure which type yours requires. Generally speaking, once these bolts/screws are removed (using a wrench) you should then be able to pull out the old blade by hand safely away from any moving parts of your machine.

When installing a new blade onto your miter saw, make sure all bits of debris and dirt are completely cleaned off before putting it in place - especially inside where it's connected to the motor shaft at either end (or both). A piece of debris can cause performance issues down the line due to maintaining contact with rotating parts such as blades or spindles during operation which isn't safe! You may need assistance when tightening up those fixing bolts/screws (as they often require more force than what fingers alone can provide). Once tightened up properly, double check that everything is secure and free of debris before switching on your saw again - its always better safe than sorry!

By following this checklist before every project using our woodworking tools we can ensure their longevity and accuracy for years to come without running into common issues caused by re-installing incorrectly done so previously😊