If you're a builder or contractor, you know that getting a perfect 2 3/4 hole saw cut is essential. And if you're a home owner, you probably know that getting a perfect 2 3/4 hole saw cut can be pretty tricky. But there's a little trick that you can use to guarantee a perfect cut every time. Here's what you need to know...

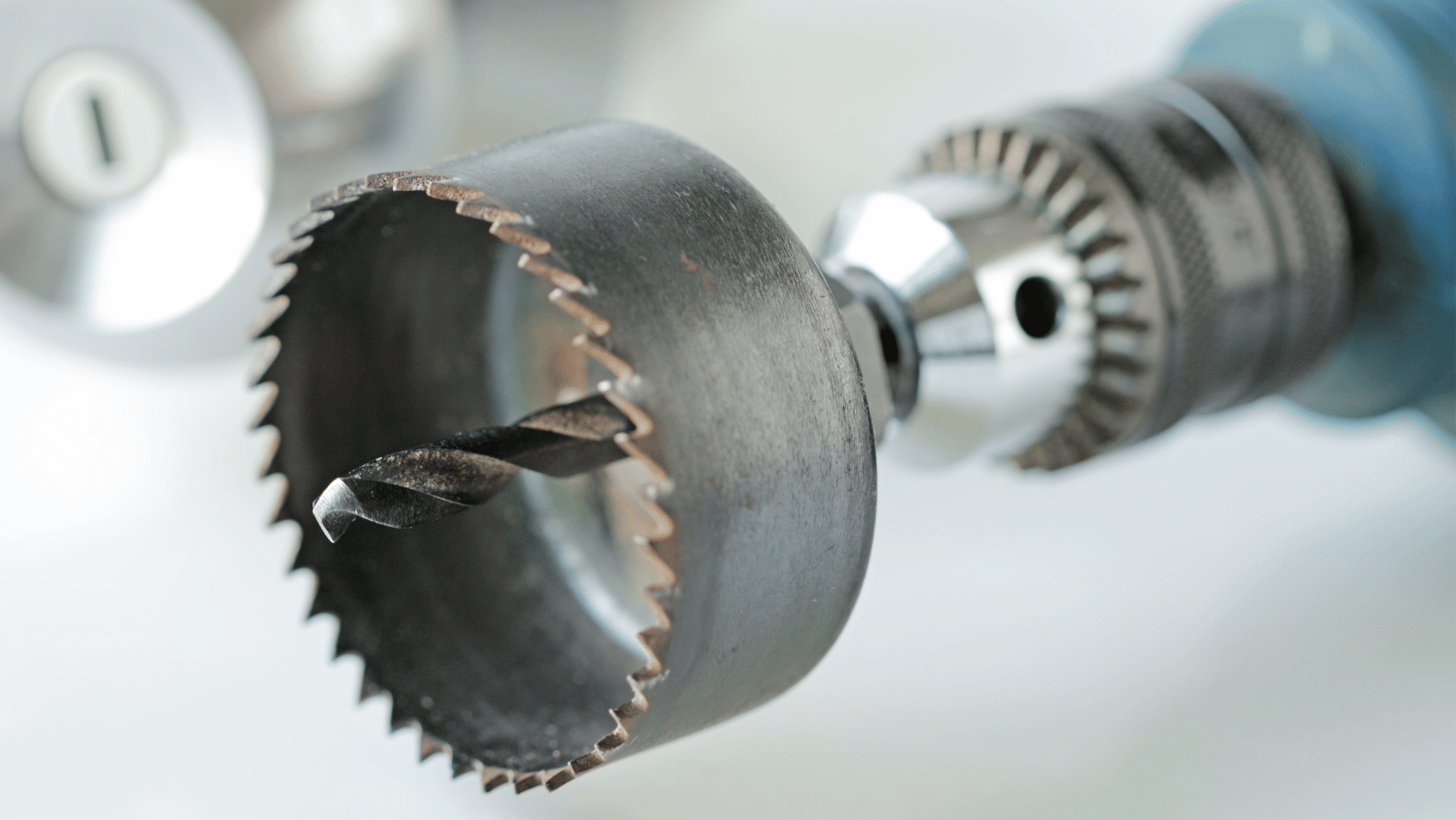

What is a hole saw and why do you need one?

A hole saw is an attachment for a drill used to create precise round holes in materials such as wood, plasterboard, metal and even plastics. Hole saws come in all different sizes, but 2 3/4" is the ideal size for most projects. Before you begin drilling with a 2 3/4" hole saw, there’s one important trick that you need to know. Make sure to use a 2 3/8" pilot bit which will make starting the 2 3/4” hole cut much easier and give you more control when drilling. Drill slowly and steadily until your 2 3/4" cut is complete. This technique will help ensure that every time you use a 2 3/4 Hole Saw it cuts perfectly every time!

The different types of hole saws available

Hole saws can be a great way to drill through a variety of materials with ease and accuracy. Depending on the project at hand, there are different types of hole saws available that can work best to complete the job. Toothed hole saws are great for creating round holes in thin sheet metal, and are perfect for tasks such as cutting out air vents and other circular openings. If you're dealing with thicker sheet metal or tubing, you may want to use a bi-metal hole saw instead since they offer faster cutting speeds while still delivering lasting durability. For tougher applications, such as drilling into cast iron, concrete or brickwork, then consider using a diamond tipped hole saw instead as their special tips will stay sharp and cut much better than standard blades. No matter the type of project you have ahead of you, having the right hole saw handy is essential for achieving a smooth finish without taking too long to do so.

How to use a hole saw for the perfect cut every time

The hole saw is an underrated tool, capable of making accurate, easy cuts essential for any job. By understanding its uses and capability, DIYers and professionals alike can use the hole saw for the perfect cut every time. When choosing a hole saw based on the size of your desired cut, remember that you can always make a larger hole smaller if needed, but it is not possible to make a smaller cut bigger. To get the most from your hole saw, be sure to mark off both sides of your board prior to making the cut and be careful not to damage either side as this may affect how straight the resulting hole will look. Once the correct size has been selected and the markings made, secure the material in one spot - good clamping enables a much cleaner cut or even leverage platforms when cutting through especially thick materials. With safety gear in place, get to drilling! When drilling through harder material such as metal or bone take breaks or ease off on bit pressure when slowing down to prevent cracking or breakage of your equipment and always observe proper waste disposal techniques afterwards. Use these tips and tricks in combination with a reliable hole saw selection and you'll achieve consistent results every time.

Tips and tricks for using a hole saw

Hole saws are incredibly handy tools that can be used to make clean and precise cuts in most materials. To ensure a successful outcome, there are some basic tips and tricks you should follow when using a hole saw. Firstly, the drill should be held firmly while cutting so the bit doesn’t twist or jump in the material. When marking your cutting points, use a center punch or scribe to give the drill bit something to grip onto before drilling. Also ensure you are drilling at correct speed – too fast may cause damage and too slow can burn out your motor, heat up the bit and make it dull more quickly. It is best to start with smaller holes and gradually increase the size of your hole saw until you reach your desired result. Finally, if possible always work from both sides of the material to prevent tear-out on weak or thin materials. If done correctly, a hole saw can greatly simplify many DIY projects!

Why you should get a hole saw if you don't already have one

Every home improvement advocate should invest in a hole saw if they don't already have one. A hole saw is an invaluable tool that allows you to cut clean, smooth-edged holes into a variety of materials including wood, plastic and thin metals. They are much faster and more accurate than traditional rotary drills when making larger holes and can even be used with specialized tips for cutting shapes like round circles. Additionally, unlike fixed-shank circular cutting blades, the adjustable, removable blade on a hole saw ensures accuracy regardless of the size of the hole being cut. With the wide range of sizes available and the unlimited uses they provide, having a hole saw in your toolkit is crucial to any job around the home.

Bi-Metal Hole Saw 2 3/4 Inch, 30 mm Cutting Depth HSS Hole Cutter for Cutting Wood, Plastic, Drywall, Plasterboard and Soft Metal Sheet, Red

🎁If you're in need of a hole saw, or are interested in getting one, hopefully this article has helped. You now know what a hole saw is and why you might need one. There are different types of hole saws available depending on your needs. And if you follow the tips and tricks we've laid out for using a hole saw, you'll be making perfect cuts every time. So don't wait any longer, get yourself a hole saw today! buy here at amazon 👇

2-3/4 Inch Hole Saw, 70mm HSS Bi-Metal Hole Cutter with Hex Shank Drill Bit Adapter for Wood Plastic Drywall Fiberboard and Soft Metal Sheet, Blue

Make your DIY projects look professional with our heavy duty 2-3/4'' hole saw! With its non-binding clean edge and sharp teeth, it'll create faster, smoother cuts than any other on the market - perfect for an even more precise finish.