Are you looking for a way to turn your logs into lumber? If so, then a chainsaw mill might be the perfect tool for you. A chainsaw mill is a device that attaches to the end of your chainsaw and allows you to cut boards straight from the log. It's a great way to turn logs into lumber without having to buy an expensive sawmill. In this post, we’ll cover everything you need to know about using a chainsaw mill, including tips and tricks from the pros.

Choosing Your Logs

The first step in using a chainsaw mill is choosing the right logs for the job. You want to select logs that are long enough, thick enough, and straight enough for your project. When selecting logs, look for ones that are free of knots and other imperfections as these will affect the quality of your lumber. In addition, try not to choose logs that contain rot or any other type of decay as these can be dangerous when working with power tools like a chainsaw.

Preparing Your Logs

Once you have selected your log, it’s time to prep for cutting. Make sure that the log is stable before you start cutting and secure it with either clamps or wedges if necessary. If possible, place your log on something flat like concrete or asphalt so that it doesn't roll while you're working with it. Once your log is secured safely in place, it's time to start cutting!

Cutting Your Logs

When cutting with a chainsaw mill, safety should always be top priority. Wear safety goggles, ear protection, gloves, and long pants/shirts when operating any kind of power tool like a sawmill. Start by slowly cutting through the top part of the log until you reach your desired depth—typically 2-4 inches deep—and then slowly work around in circles until you reach full depth all over the log. Once you've reached full depth all around the circumference of the log, begin cutting out each board one at a time from top to bottom according to your desired measurements and widths until all boards are cut out from the log accordingly.

Conclusion:

Chainsaw mills are an incredibly useful tool for turning logs into lumber quickly and easily without breaking the bank on expensive sawmills or woodworking machinery. With just some basic knowledge about choosing logs and preparing them for cutting as well as some safety tips from experienced woodworkers, anyone can use their own chainsaw mill successfully at home! So don't wait—try out this helpful tool today!

Raving Tools Questions:

What is your favorite thing to mill with a chainsaw mill?

For me, my favorite thing to mill with a chainsaw mill is cedar lumber!

I love the way the saw blades hug the grain of the wood as I move it through. The result always looks so beautiful and professional - like something you could buy in a store! Plus, working with cedar provides such a great scent while I work that's calming and invigorating at the same time.

Plus, there's something so satisfying about taking something natural and transforming it into usable pieces of lumber for any type of project. Whether it be an outdoor fence or deck, furniture pieces like tables or chairs, frames for doors and windows, cabinetry and shelving - cedar is incredibly versatile for any kind of application you can think up.

And because cedar tends to have fewer knots than other woods when cutting with a chainsaw mill (which makes for easier cuts), it allows you to get more uniform boards without having to manually turn around knots during your pass throughs on each side resulting in better end product faster. It really helps speed up production times!

Overall, I just find that cutting up some old growth Western Red Cedar logs is one of the most rewarding things I've ever done using my chainsaw mill - both artistically and financially too!

2. What type of wood do you usually chainsaw mill?

When it comes to chainsaw milling, I usually opt for softwoods. Softwoods are easy to work with and usually easier on your saw blades and other tools. Some of the most popular types of softwood that I use include cedar, redwood, pine, cypress, spruce, and fir. All of these woods have a relatively low strength rating compared to hardwoods like oak or maple which makes them perfect for chainsaw milling because they don’t require as much effort when cutting through them with a chainsaw.

Aside from softwoods, there are also some hardwoods that you can mill effectively with a chainsaw - namely sweetgum (Liquidambar), beech (Fagus) and walnut (Juglans). The key is to make sure you get good quality lumber that is dry enough so that it doesn’t bind up your chain or cause too much wear on your saw blade.

Finally, one thing to keep in mind is that the type of wood matters just as much as the grade - knots, splits and other impairments can reduce yield significantly if all precautions aren’t taken beforehand. For example - cutting green wood means more strain on your equipment since green wood has a higher moisture content than dry wood; this will eventually dull blades faster resulting in less precision cuts during processing. So take precautions accordingly especially when dealing with valuable hardwoods such as Walnut or Oak!

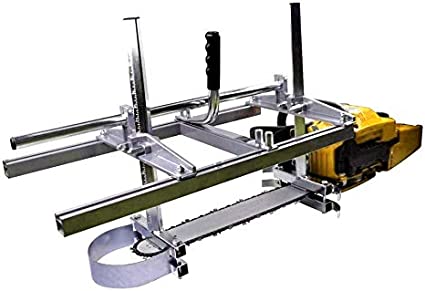

Chainsaw Guide Tool Mill Chain Saw Accessories Chainsaw Mill Portable Excellent Workmanship Chainsaw Accessories for Cut Wood Strips Effectively

3. How do you go about choosing the right chainsaw mill for the job?

Choosing the right chainsaw mill is an important part of any woodworking project. Depending on your specific needs, it's essential to determine what type of mill will work best for you. There are a few key factors that should be taken into consideration when selecting the proper chainsaw mill.

First and foremost, consider what kind of lumber you need to cut with your chainsaw mill and the size of timber you want to produce. If larger timbers are needed, opting for a larger chainsaw mills would be ideal since they can handle bigger logs up to 24 inches in diameter or longer in length. Choose one that offers various options for adjustable cutting thicknesses as well as maximum versatility in accommodating varying lengths and sizes of timber.

Secondly, determine whether or not maneuverability is important for your particular situation. For instance, if you plan on felling trees with large trunks (e.g., live oaks) then a portable sawmill may be necessary due to its mobility and flexibility compared to conventional mills that require more setup time and effort while working farther away from the site where it will cut lumber pieces at higher altitudes such as mountain terrain or rolling hillsides. Additionally, ensure that safety features have been implemented such as guards around blade areas or kickback bars designed specifically for using power tools like chainsaws safely while minimizing potential hazards during operation times; these features can help protect both operator(s) & bystanders alike during operations involving hazardous power equipment like a chainsaw based sawmill setup!

Finally, look at other aspects such as cost efficiency when choosing which type/size/make & model is right for your job & budget requirements – often times lighter weight yet strong construction materials used may allow some chain saws & their associated mills save significantly on shipping costs compared against heavier steel framed sets resulting in lower overall price tags but still deliver reliable performance outputs desired by many sector professionals requiring precision cutting consistently over long hours spent generating those boards from large tree logs being processed through them! This just goes to show how doing research upfront into picking out appropriate hardware instruments can truly pay off big dividends down line when all’s said done; Happy Sawing!!!

4. What are your tips for getting the most out of a chainsaw mill?

Congratulations on your interest in chainsaw mills - they are a great way to turn logs into slabs of wood for projects. Here are my top tips for getting the most out of your chainsaw mill:

Start with the right chainsaw – Make sure that you use a high-powered, gas-driven chainsaw with enough power to handle the milling job. Look at its cubic centimeter, or cc rating and make sure it's over 50cc.

Select good quality wood – The quality of wood is important when working with your mill. Choose straight pieces that have few knots and blemishes, as these will produce better results when cut through a mill. Avoid using wet or twisted pieces of wood as much as possible!

Sharpen Your Chain – It's very important to sharpen your chain before each use; this will ensure you get optimal performance from the sawmill and reduce wear on both the saw and blade itself too! Sharpening kits can be easily found online or at specialty stores for less than $20 bucks so it is worth investing in one if you plan on doing lots of milling work. Use a round file to keep things sharpened up between sessions correctly following manufacturer instructions always carefully .

4 . Secure Your Wood Logs Properly– Always securely attach logs onto the bed plate so they don’t move while being milled; not only could this cause damage to equipment but it could be dangerous as well! Consider using clamps or ratchet straps depending on size/weight /security needed..

5 . Don't Overwork Yourself– Take regular breaks while cutting large logs; this will help prevent injuries due o fatigue caused by extended periods without rest,, plus an added bonus some time away allows helps maintain focus during longer more demanding jobs , allowing him time to check his cuts regularly..

5. Do you have any experience using a Badger Mill? If so, what are your thoughts?

Yes, I do have experience using a Badger Mill. My overall thoughts on the mill are quite positive and I would highly recommend it.

The Badger Mill is designed for maximum efficiency and accuracy with each project you take on. It offers top-of-the-line features that make your work easier and more precise, allowing for faster results without compromising quality. The machine has a powerful motor, robust construction and controllable cutting speeds that give you greater control over the process of machining your materials. Plus it's equipped with advanced safety features to protect both you and your work from harm while in use.

Aside from its performance capabilities, the real beauty of this machine lies in its versatility. It can be used to produce parts for all manner of applications including automotive components, aerospace equipment or precision medical instruments like screws or implants – virtually anything that needs accurate cutting or shaping can be done quickly with this device! The device also comes with several helpful accessories such as an onboard tool magazine which makes changing tools much simpler than before, a dust collection system to keep operation area clean during use and even an interface panel so operators can adjust settings quickly according to their exact needs at any given moment.

In short - if you're looking for a reliable milling machine that won't let you down then the Badger Mill should certainly fit the bill! With its impressive performance capabilities combined with essential safety features, easy integration into existing manufacturing processes as well as minimal setup time required - it really is one of the best options out there when it comes to producing high quality parts in a timely fashion at competitive prices!

Portable Chainsaw Mill Planking Milling, Aluminum Steel Saw Mill from 14'' to 36'' Guide Bar Planking Lumber Cutting Tool,Chainsaw Mill for Builders and Woodworkers